While all modern-day cars use computer-controlled fuel distribution systems, there are still many vehicles when traveling that utilize the typical carbureted approach of gas shipment. Before digitally controlled fuel systems were developed, automobiles depended on mechanically operated gas shipment systems, sometimes in carburetors, to provide the engine with gas.

While carburetors are not indeed considered widespread any longer, for lots of decades, they were the favored approach for fuel distribution, and working with them was a much more typical event. Although very few vehicles with carburetors stay on the road, the ones that do must be correctly tuned and adapted to achieve optimal efficiency.

Carburetors can go wrong for numerous reasons. Nevertheless, adjusting the carburetor is a reasonably straightforward work that can be done with a whole collection of hand tools and also a little bit of technical knowledge. This post shows you exactly how to adjust the air-gas mixture and the idle airspeed – the two most usual changes made when tuning a carburetor.

Part of 1: Adjusting your carburetor.

- Products Needed

- Safety glasses

- Screwdriver variety

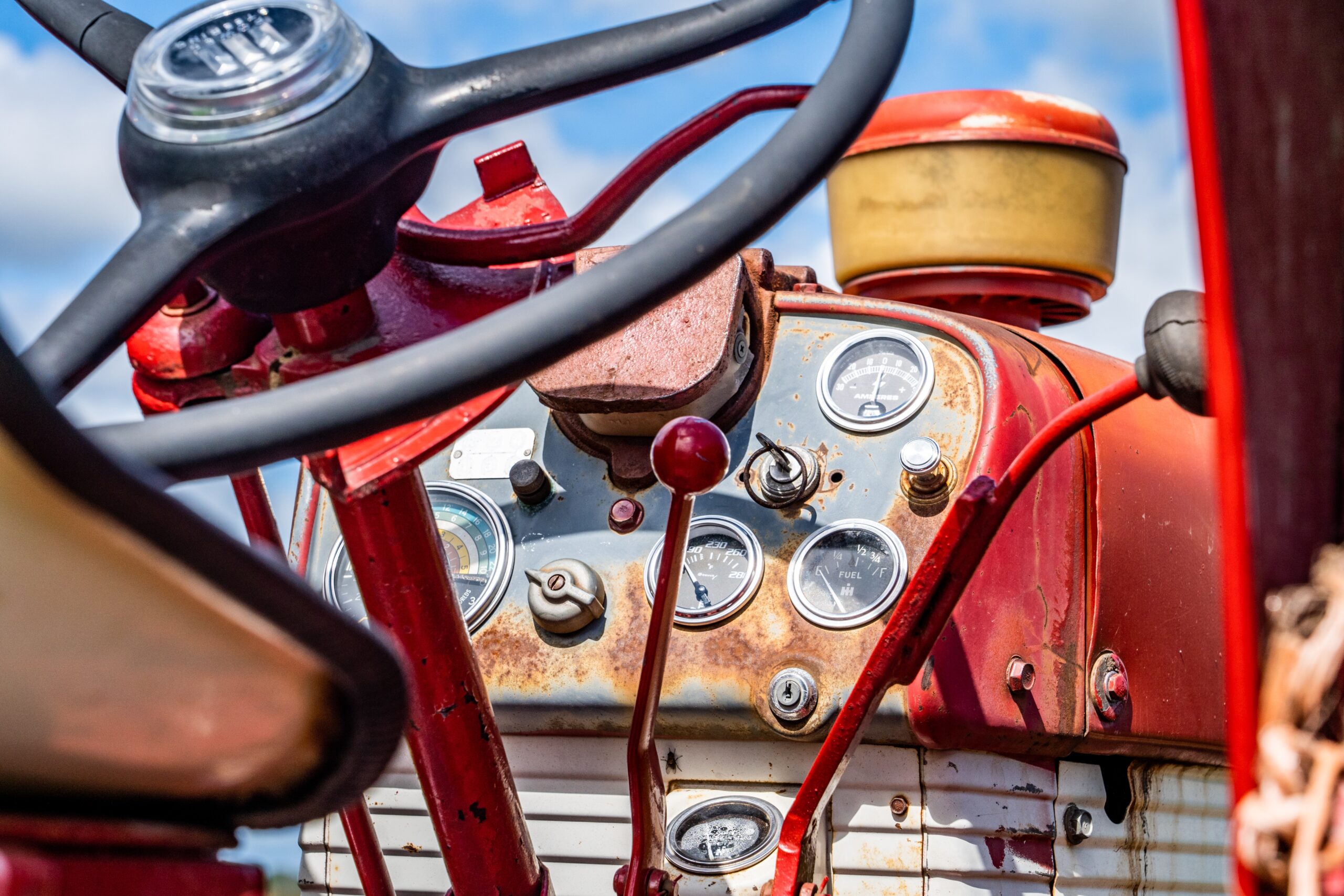

Step 1: Remove the engine air filter. Situate and get rid of the engine air filter and real estate to access the carburetor.

This might need using hand tools. However, the air filter and housing are often safeguarded using only a wing nut that can commonly be removed without using any device.

Step 2: Adjust the air-fuel combination. Utilize a level head screwdriver to readjust the air-gas mixture.

When the air filter has been eliminated, and the carburetor is subjected, find the air-gas mix change screws. These are often simple, flat head screws.

Relying on the make and version of the vehicle, different carburetors may have numerous, sometimes up to 4, air-fuel mix adjustment screws.

These screws control the amount of gas that enters the engine, and inappropriate adjustment will lead to decreased engine performance.

Tip: Carburetors might have numerous screws, so describe the service guidebook to guarantee that you have correctly situated the screws to prevent making incorrect modifications.

Step 3: Observe the engine’s condition. Beginning the lorry and allow it to warm up to running a temperature.

Remember the running condition of the engine. Utilize the table below to establish if the engine is running lean or rich.

Whether the engine is running lean or rich will help you make the appropriate modifications for best engine performance. This will certainly let you understand if it is deprived of gas or is utilizing an excessive quantity.

Suggestion: If you are still uncertain concerning your engine’s problem, you may intend to get the help of a certified mechanic to examine the engine to prevent making incorrect adjustments to the carburetor.

Step 4: Readjust air gas combination screws. As soon as the engine has come to operating temperature, return to the carburetor and readjust the air-gas combination screw or screws.

Tightening up the screw increases the quantity of fuel, while loosening up lowers the amount of gas.

It is likewise vital to make any adjustments in small increments of a quarter turn when making any adjustments.

This will prevent any significant fuel changes that can considerably influence the efficiency of the engine.

Back the modification screws off till the engine is running somewhat lean.

Pointer: When the engine is running slightly lean, the rpm will go down, the engine will undoubtedly start to run rough, pop, and sputter until it delays.

Withdraw the mix screw till the engine begins to present symptoms of a lean mix, and afterward tighten them down, in quarter-turn increments, till the machine runs efficiently.

Idea: When the engine is running efficiently, the still rate will certainly stay consistent, and the engine will run in a smooth, well-balanced fashion, with no misfires or trembling. It must likewise rev efficiently through the complete rpm variety with no misfires or shakes when applying throttle.

Step 5: Test the engine at idle and while revving—Rev the engine up after every change to see if it remains to run efficiently at greater RPMs.

If you observe any vibration or trembling, remain to make changes until the engine runs smoothly both at still and while revving, with the complete rpm range.

Your throttle feedback should also be crisp and responsive. The engine needs to rev efficiently and also quickly as you use the throttle.

More changes are required if the car presents any sort of slow performance or misfires when you use the throttle.

Warning: If there are several screws, it is essential to attempt and also readjust them all by the same quantity of increments. Keeping all of the changed screws tuned as carefully with each other as feasible will undoubtedly ensure that the gas is dispersed into the engine as equally as possible, producing the smoothest performance and procedure across all engine rates.

Step 6: Locate the still blend screw. As soon as the air-fuel mix screws have been effectively changed and the engine runs efficiently between idle, and when revved, it is time to find the idle bleed screw.

The idle combination screw regulates the air gas blend at a still rate and usually lies near the throttle plate.

Idea: The precise place of the idle mixture screw can differ commonly amongst makes and designs, so refer to the proprietor’s guidebook if you aren’t specific about where the idle mixture screw is. This will undoubtedly ensure that no inaccurate changes are made that could negatively impact the engine’s efficiency.

Step 7: Adjust idle blend screw until you accomplish a smooth still. When the still mix screw has been recognized, change it till the engine is idling smoothly, without misfires or drinks, and at the correct rate.

In much the same way as making the air-gas combination change, back the idle mixture screw off right into a lean condition, and then change it in quarter-turn increments, up until the wanted still speed is accomplished.

Pointer: If you are not exactly sure what the still speed specification should be, refer to the owner’s guidebook for direction, or merely change the screw till the engine is idling at efficiently, and also does not drop significantly in rpm or delay out when revved from idle. Take into consideration having a professional evaluate your engine’s idle if you are still having issues.

Step 8: Reinstall the air filter as well as examination drive the vehicle. Once all the modifications have been made, and the engine runs smoothly throughout all engine rates, reinstall the air filter and real estate onto the carburetor and examine drive the lorry.

Keep in mind any adjustments in the lorry’s power outcome, throttle reaction, as well as fuel consumption. If need be, return as well as make any necessary changes till the vehicle is running smoothly.

All points taken into consideration, readjusting a carburetor is a reasonably straightforward job that can be performed independently. Nevertheless, suppose you are not comfy making modifications that are critical to your engine’s efficiency. In that case, this is a job that any type of expert specialist, such as one from YourMechanic, must be able to execute. Our technicians will positively have the ability to check and change your carburetor or perhaps change the carburetor if any severe mistakes are found.